From bulldozers, earthmovers and excavators to mobile cranes and pavers, the vast majority of North America’s construction equipment is fuelled by diesel. In the US, construction actually makes up 55% of off-road fuel use, according to the Diesel Technology Forum.

A few years ago, this might have been a bad thing for the environment. But since 2014, when the US Environmental Protection Agency (EPA) introduced mandatory Tier 4 standards for new off-highway diesel engines and heavy equipment, this has all changed.

Diesel manufacturers have transformed construction equipment into much greener machines by introducing high-tech emissions control devices called DPFs and DOCs. These filter the exhaust gas from your heavy equipment with a series of catalytic converters, reducing toxic elements like carbon, soot, and particulate matter. And it’s not just the environment that benefits! Better air quality on construction sites and increased fuel efficiency benefit everyone from site managers to heavy equipment operators.

What to Do About a Faulty Construction DPF?

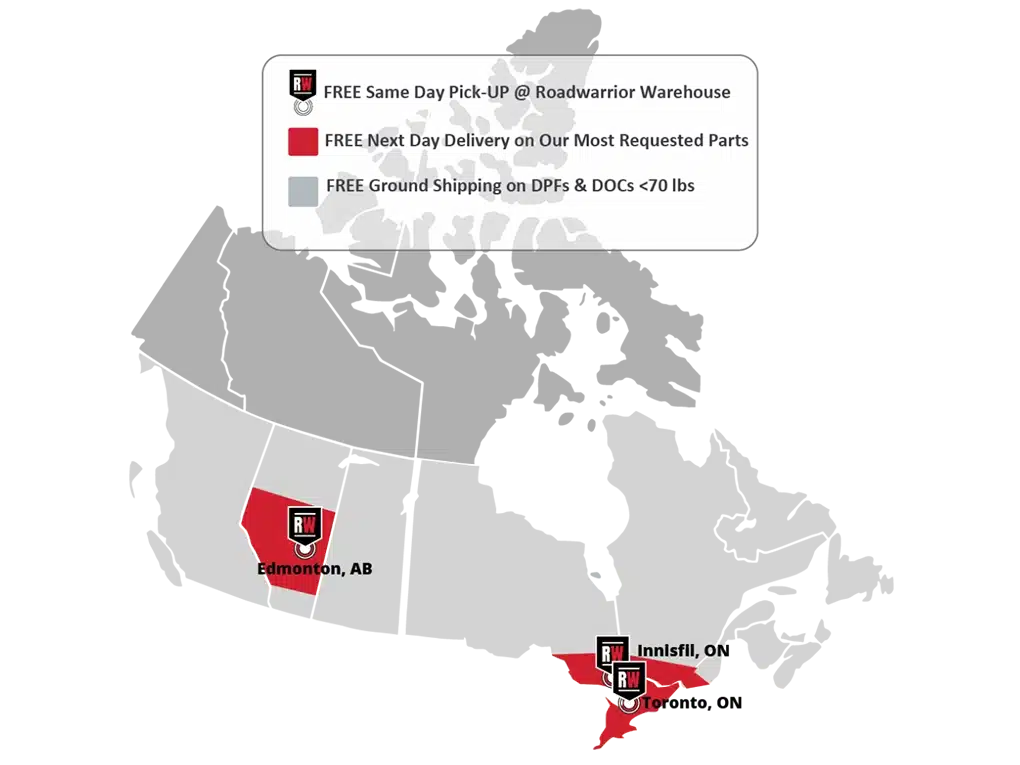

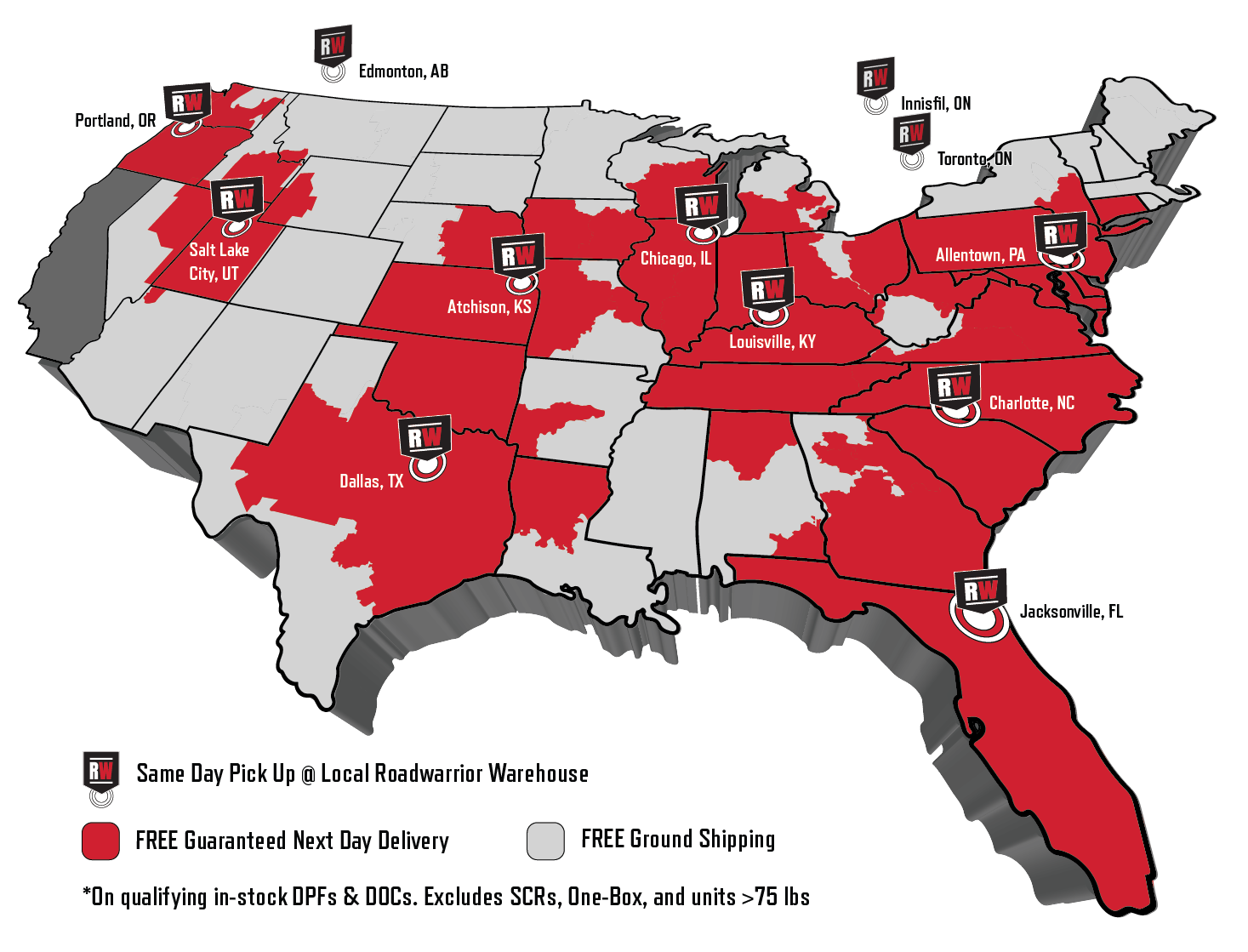

DPF filters have many benefits, but your DPF often has a shorter working life than your heavy equipment. That’s where we come in. As the only aftermarket firm to offer DPFs for construction equipment, we’re here to get you back on track! You can order a new Roadwarrior DPF from your parts supplier and we’ll ship it to your site in 1-2 days. You can also find out more about the benefits of our DPFs here.

What Are Emissions Control Devices?

Most construction equipment includes a DPF (Diesel Particulate Filter), and a DOC (Diesel Oxidation Catalyst). These honeycomb-structured filters are coated with platinum-grade metals to make them catalytic converters. As the hot exhaust gas passes through, the filters trigger a series of reactions that oxidize and purify it. Aftertreatment systems mean cleaner exhaust emissions, which keep your heavy equipment running smoothly and the air you breathe fresher.

What Problems Occur with A Construction Aftertreatment System?

While this is a brilliant system, you can encounter problems, especially with your Diesel Particulate Filter. Hot exhaust gas flows through the DPF, which traps soot and fine particulate matter. Commercial trucks reach high speeds on long highways, which then lets the engine get hot enough to burn the soot off the DPF—this is called passive regeneration (regens).

Off-highway machines, like heavy-duty construction equipment, rarely get hot enough for passive regens. This means that some models can only burn off soot with active regens. Active regeneration (regens) is when a small amount of fuel is injected into the exhaust stream to heat it up and burn the soot off the filter.

When enough ash has built up on the DPF, you will need to have it removed and cleaned. This normally happens after 3,000-4,000 hours in typical construction equipment and about 250,000–500,000 miles in trucks. If this doesn’t happen, soot and ash will accumulate on the DPF until it clogs, cracks and eventually fails.

Cleaning can significantly increase the life of your DPF, but eventually, it will need replacing. Instead of contacting the original manufacturer, why not ask for Roadwarrior DPFs? Our models are designed as exact-fit replacements for major manufacturers including Caterpillar and Cummins and come at competitive prices, saving you money and downtime. We make our DPFs with advanced Metalcor® catalyst technology and design them to meet or exceed OEM standards. For your peace of mind, they also come with a hassle-free warranty.