The Selective Catalytic Reduction (SCR) system is integral to maintaining the operational efficiency of heavy-duty diesel engines, serving a critical function in managing nitrogen oxides (NOx) emissions. This advanced technology, utilizing Diesel Exhaust Fluid (DEF), ensures engines meet stringent emission standards without sacrificing performance. However, the system’s complexity necessitates vigilant maintenance to prevent issues that could hinder engine function and efficiency.

When an SCR system flags a fault code like P20EE00 – SCR NOx Catalyst Efficiency Below Threshold, it’s signaling a reduction in the system’s ability to process NOx effectively. Addressing these fault codes promptly isn’t just about compliance; it’s crucial for maintaining the engine’s power output and fuel efficiency. Understanding the cause and implementing a fix are key to avoiding downtime and ensuring your truck remains a reliable asset in your operations.

What is an SCR and How Does It Work?

The Selective Catalytic Reduction (SCR) system is a cornerstone of modern diesel engine technology, designed specifically to tackle the challenge of reducing nitrogen oxides (NOx) emissions. NOx, a byproduct of diesel combustion, is targeted for reduction due to its contribution to air pollution and its role in the formation of smog and acid rain. The SCR system addresses this by introducing a secondary chemical reaction outside of the combustion process, specifically within the exhaust system, to neutralize these harmful emissions.

The chemical reaction of the SCR process is facilitated by Diesel Exhaust Fluid (DEF), a solution comprised mainly of urea and ionized water. When injected into the exhaust stream, DEF vaporizes and decomposes to form ammonia. As the exhaust gases mixed with ammonia pass over the SCR catalyst, a chemical reaction occurs, converting NOx into two harmless components: nitrogen and water vapor. This reaction effectively cleans the exhaust gas before it exits the tailpipe, significantly reducing the emission of NOx and helping diesel engines meet stringent environmental regulations without compromising their power or efficiency. The SCR system, therefore, plays a pivotal role in enabling heavy-duty diesel vehicles to achieve both regulatory compliance and operational precision.

Common Causes of SCR System Failure

- Use of Substandard DEF: The integrity of the SCR system hinges on the use of high-quality Diesel Exhaust Fluid (DEF). Inferior DEF can lead to deposit buildup within the SCR catalyst, impeding its ability to reduce NOx emissions. Ensuring the use of DEF that meets industry standards is crucial for maintaining system efficiency.

- Inaccurate DEF Dosing: Precision in DEF dosing is vital. Incorrect dosing, due to issues such as miscalibration, sensor inaccuracies, or faulty injectors, can result in ineffective NOx reduction and even damage the catalyst. Here, Roadwarrior DEF dosers come into play, offering high-quality, affordable solutions that ensure precise DEF dosing, giving operators quick and easy peace of mind.

- Component Degradation: The demanding conditions under which SCR systems operate can accelerate wear on critical components, such as DEF injectors and NOx sensors. This degradation can compromise the system’s functionality, emphasizing the importance of routine checks and timely component replacement.

- Exhaust System Leaks: Leaks in the exhaust system, particularly before the SCR unit, can introduce unfiltered exhaust gases directly to the catalyst, risking thermal and chemical damage. Utilizing high-quality clamps and gaskets from Roadwarrior can prevent such leaks, safeguarding the SCR system’s integrity and performance.

Mitigating these risks through vigilant maintenance, the use of high-quality DEF, and ensuring the proper functioning of all system components, including utilizing Roadwarrior’s reliable DEF dosers and exhaust clamps and gaskets, is essential. Such measures not only protect the SCR system from common failure modes but also maintain the engine’s efficiency and compliance with emission standards, ensuring vehicles remain operational and efficient on the road.

Fault Codes Triggered by Volvo or Mack SCR Catalyst

Understanding SCR fault codes is paramount in ensuring the operational health and efficiency of heavy-duty diesel engines, particularly those powering Volvo and Mack trucks and select construction machinery. These engines, renowned for their durability and performance, rely heavily on the Selective Catalytic Reduction (SCR) system to meet stringent emission standards. However, when the system signals a fault code, it indicates underlying issues that could compromise not just compliance with these standards, but also the overall performance and efficiency of the engine. Let’s explore the specifics of each code and its implications for Volvo and Mack diesel engines, shedding light on the steps needed for troubleshooting and maintenance to keep these powerhouses running smoothly.

P100400 – SCR NOx Catalyst Efficiency Moderately Below Threshold This fault code indicates that the efficiency of the SCR NOx catalyst is slightly below the acceptable threshold, but not to a critical extent. It suggests that the SCR system is not converting NOx gases into nitrogen and water vapor as efficiently as it should. This inefficiency can lead to increased NOx emissions, potentially affecting the engine’s performance over time. Troubleshooting steps often involve checking the DEF quality and dosing system for issues, inspecting the SCR catalyst for deposits or damage, and ensuring there are no exhaust leaks affecting the system’s operation.

P20EE00 – SCR NOx Catalyst Efficiency Below Threshold More severe than P100400, the P20EE00 code signifies that the SCR catalyst’s efficiency has significantly deteriorated, impacting the engine’s ability to comply with emission standards. This fault code is a red flag that immediate attention is required to prevent further damage and ensure the engine remains within legal emission limits. Addressing this code typically involves a more in-depth investigation, including a thorough examination of the SCR catalyst, DEF dosing system, and potential issues with the EGR system that might contribute to higher NOx levels.

P103C00 – SCR NOx Catalyst Efficiency Inducement The inducement mode triggered by this code is a critical engine management response designed to prompt immediate action to address the SCR system’s inefficiency. When this code is set, the engine’s power may be limited, or other operational restrictions may be applied to encourage prompt repair. The inducement mode signifies the SCR system’s inability to reduce NOx emissions effectively, posing a direct threat to the engine’s operational compliance and efficiency. Urgent steps must be taken to diagnose and rectify the issue, often requiring a comprehensive check of the SCR system, including DEF quality, SCR catalyst condition, and the overall health of the exhaust aftertreatment system.

Addressing these fault codes promptly and effectively is essential for maintaining the performance, compliance, and reliability of heavy-duty diesel engines. Regular maintenance, coupled with the use of high-quality replacement parts like those offered by Roadwarrior, can help prevent these issues and ensure the SCR system functions optimally.

Affected Volvo and Mack Engine Models

SCR fault codes, particularly P100400, P20EE00, and P103C00, pose significant challenges across a range of Volvo and Mack diesel engines, underscoring the importance of vigilance and maintenance in these systems. These codes are not isolated to any single model, affecting a broad spectrum of vehicles in both the trucking and construction sectors. Here are examples of specific engine models where these fault codes are commonly encountered:

Volvo D13 Engines Found in a variety of Volvo’s flagship trucks, the D13 engine is known for its power and efficiency. However, it’s also susceptible to SCR system issues, highlighted by the fault codes mentioned. This engine’s widespread use in long-haul operations makes understanding and addressing these codes crucial for maintaining operational efficiency.

Volvo D11 Engines Another engine frequently experiencing these SCR fault codes is the Volvo D11, utilized in regional haul and vocational trucks. The D11 combines fuel efficiency with durability, and keeping the SCR system in top condition is key to leveraging these benefits.

Mack MP8 Engines The Mack MP8 engine, revered for its power and torque, is a workhorse in both highway and construction applications. SCR fault codes in the MP8 can significantly impact its performance, making early detection and resolution critical.

Mack MP7 Engines Designed for versatility, the MP7 engine powers a wide range of Mack trucks. This engine is also prone to SCR system issues, necessitating regular checks for fault codes to avoid potential downtimes.

These engines represent just a fraction of Volvo and Mack’s offerings, but they underscore the pervasive nature of SCR system concerns across the industry. Whether powering trucks across the country’s highways or operating on construction sites, addressing SCR fault codes in these engines is pivotal to ensuring they continue to meet performance and emission standards. Recognizing the symptoms and implications of these fault codes can help operators and service technicians take proactive steps to mitigate issues, ensuring the longevity and efficiency of Volvo and Mack diesel engines.

Experts Recommend Roadwarrior’s SCR Replacement

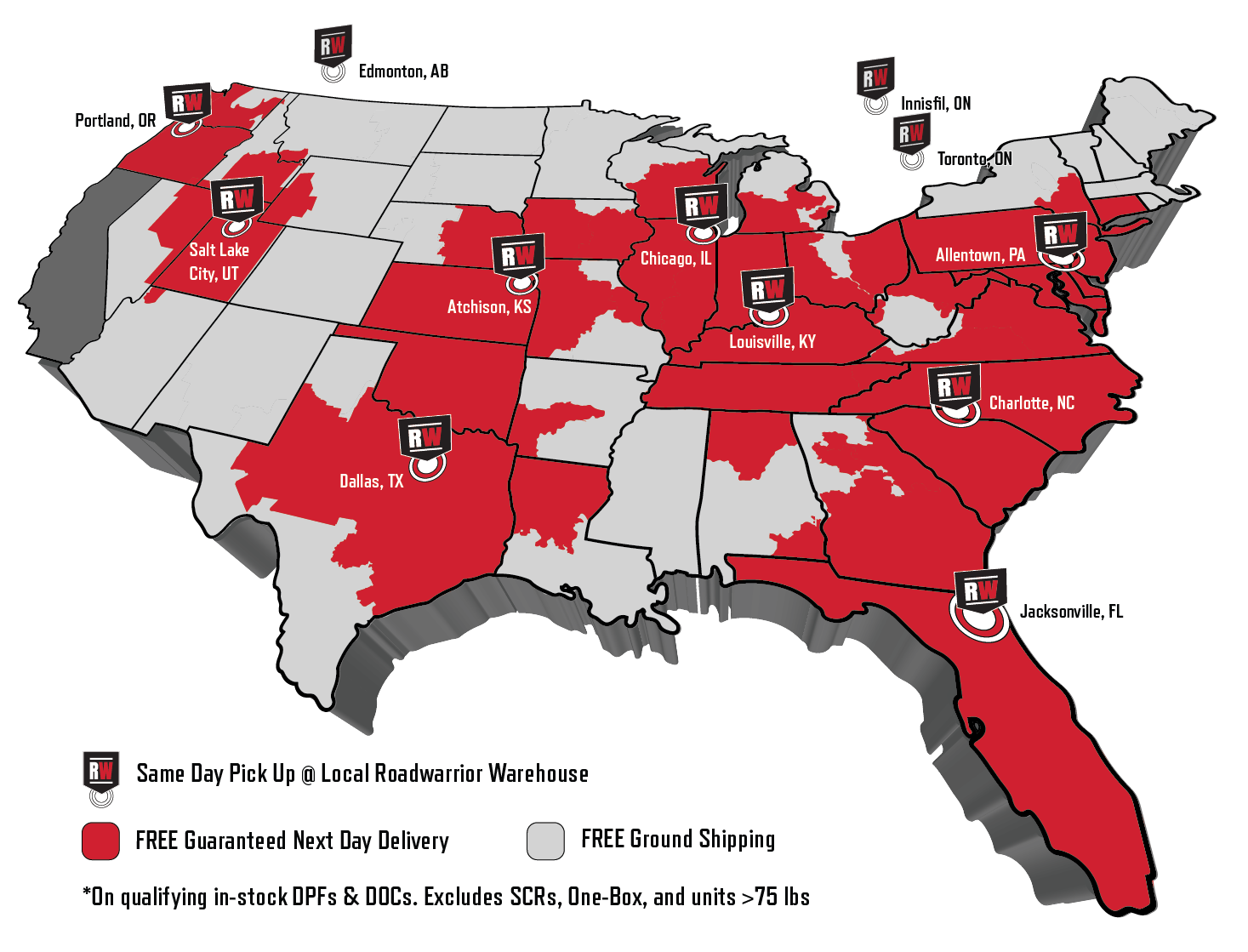

Addressing SCR fault codes in Volvo and Mack diesel engines, Roadwarrior’s C0179-SC offers a reliable replacement for Volvo’s parts 21311953 or 21311951. Designed for seamless compatibility with these engines, the C0179-SC matches OEM performance, ensuring engines remain efficient and compliant with emissions standards. Opting for Roadwarrior’s SCR replacement not only guarantees OEM-equivalent performance but also provides significant cost savings. This makes the C0179-SC an economical choice for operators looking to maintain their vehicles’ performance and emission compliance without overspending. Roadwarrior delivers a practical, cost-effective solution for keeping your engine in top condition.

Emissions Expert, Ryan Fox, on Volvo SCR Modules

In an insightful instructional video, Ryan Fox, a seasoned heavy diesel mechanic specializing in aftertreatment emissions, demonstrates the effective resolution of the P20EE00 fault code using Roadwarrior’s SCR replacement part, C0179-SC. Fox’s hands-on approach not only simplifies the technical process of SCR module replacement but also underscores the compatibility and efficiency of using Roadwarrior parts in Volvo and Mack engines. This practical guide is invaluable for technicians and operators looking to address SCR system issues with confidence. For a step-by-step visual walkthrough of the entire replacement process, viewers can access the video at Ryan Fox’s SCR Replacement Video, offering comprehensive insights into tackling one of the most common SCR-related challenges in the industry.

The Domino Effect: SCR Failure Consequences

Ignoring SCR fault codes, such as P20EE00, doesn’t just risk non-compliance with emissions standards; it sets the stage for a domino effect that can severely impact engine performance. One of the most immediate consequences of unaddressed SCR system issues is engine derate P103C00, a protective measure where the engine’s power output and efficiency are intentionally reduced to prevent further damage. This derate can significantly diminish operational efficiency, leading to decreased fuel economy and reduced hauling capacity—critical setbacks in any trucking operation.

The implications extend beyond just performance. Continuing to operate with a compromised SCR system escalates the risk of extensive damage to the aftertreatment system itself, potentially necessitating costly repairs or complete system replacements. The cost associated with these repairs, both in parts and downtime, can dwarf the expense of addressing the initial fault codes.

Timely action upon detecting SCR fault codes is not just recommended; it’s essential. Early diagnosis and intervention can prevent the cascading effects of SCR failure, preserving the engine’s power, operational efficiency, and compliance with emissions standards. It underscores the importance of routine maintenance and vigilance, ensuring that SCR system issues are resolved before they escalate into more significant problems.

Ensuring Peak Performance with Roadwarrior

Ensuring the SCR system functions correctly is pivotal for optimal engine performance and adherence to emissions regulations. Roadwarrior stands at the forefront of providing dependable, high-quality SCR solutions tailored for the rigorous demands of heavy-duty trucks. Our dedication to quality reflects our commitment to helping operators maintain their vehicles at peak efficiency while complying with environmental standards. We invite you to delve into the Roadwarrior blog, where you’ll find a trove of expert advice on SCR maintenance and a deeper understanding of aftertreatment emissions systems, equipping you with the knowledge to navigate the complexities of modern diesel engines confidently.