Heavy-duty aftertreatment systems work with your diesel engine to reduce emissions and increase efficiency. The two systems are interlinked, allowing them to work much more effectively together. However, this also means that if there are issues with one system, they can affect the other. Untreated upstream issues can damage your aftertreatment devices, which in turn can disrupt your engine.

‘…watch out for common upstream issues..’

Problems with your aftertreatment system can cause increased engine backpressure, reduced efficiency and excessive regens. If the problem isn’t fixed quickly, it can end with expensive repairs and unscheduled downtime. Stay on top of system faults and avoid damaging your aftertreatment system by watching out for these common upstream issues!

Upstream Issues with Airflow

Soot buildup on the DPF filter is burnt off during passive or active regens, leaving only a small ash residue. This ash builds up over time, so we recommend a professional DPF clean at around 250,000 miles to remove it. If the ash isn’t removed, the DPF will become clogged. This causes a buildup of pressure, which will eventually crack the DPF’s surface and risk derating your engine.

The balance of air and diesel upstream influences the exhaust flowing through the DPF. Dirty air filters restrict the flow of air into the fuel. This results in the engine generating more soot, and ash accumulating much faster on the DPF. The same problem also occurs if faulty fuel injectors introduce too much diesel into the fuel stream, so the engine runs on over-rich fuel.

Another common problem is air leaks in the intake and exhaust systems, which change the balance of the exhaust gas. This affects the engine’s combustion efficiency and its aftertreatment system. Disrupting the air-fuel balance means the engine burns more fuel than necessary and creates more soot. This reduces your fuel efficiency and overloads the DPF and DOC with a soot-rich exhaust stream. We’d recommend including a check for air leaks in your routine maintenance.

Engine Oil and Technical Troubleshooting

Engine oil, coolant, and DEF (diesel exhaust fluid) are essential for a smooth-running diesel engine. However, if they’re low-quality or contaminated with debris, they can damage your heavy machinery.

Contaminated oil can become sludge-like, causing excess ash buildup and even hydrocarbon poisoning in the DPF. The result is premature DPF cleaning or even permanent damage to your aftertreatment system. Testing your engine oil can prevent your DPF from becoming clogged and stop time-consuming regens from cutting into your uptime.

To keep your fleet running smoothly, choose the right oil and include engine oil analysis in your regular maintenance. We’d also recommend checking if your engine is compatible with a low-ash or low-SAPS oil; this can keep your DPF cleaner and increase the time between regens.

Coolant Causing Aftertreatment Issues

Engine coolant is another potential cause of hydrocarbon poisoning, which can deactivate your DPF (Diesel Particulate Filter) or DOC (Diesel Oxidation Catalyst). Coolant plays an important part in protecting the engine, transferring heat and adsorbing the extreme temperatures generated by it. However, if the EGR cooler is leaking internally, it can push coolant into the exhaust system, damaging the turbo and filling the DPF with coolant.

A malfunctioning EGR (exhaust gas recirculation) can disrupt the vehicle’s air-fuel ratio. This in turn disrupts your engine and clogs up your aftertreatment system. A faulty EGR valve increases the engine’s production of particulate matter, causing more soot buildup on the DPF and more regular regens. The malfunctioning EGR can also reduce your power and acceleration, decreasing your fuel efficiency.

A damaged turbocharger limits the compressed air getting into the engine, restricting the engine’s fuel consumption and its power. There’s also a risk that it’ll leak engine oil into the aftertreatment system, poisoning the DPF. If you think you may be losing coolant internally, we’d advise troubleshooting for leaks. It’s important to find the leak before it causes any serious damage to your engine or exhaust system.

DEF Disruptions to Your SCR Catalyst

A final essential fluid that can cause upstream issues, and thereby issues for your aftertreatment system, is DEF. If the diesel exhaust fluid injector becomes blocked, the DEF can’t reach the SCR, stopping the SCR working properly. We’d advise inspecting your DEF doser for blockages if you suspect the Selective Catalytic Reduction system isn’t working properly.

‘… DEF crystallization is the biggest cause of SCR failure…’

DEF has a one-year shelf life and has to meet the optimum quality standards for your heavy equipment. If your DEF fluid is low-quality or out of date, you can also experience DEF crystallization on the SCR. DEF crystallization is the biggest cause of SCR failure. Replacing or fixing an SCR system is expensive maintenance. You can avoid this unnecessary downtime by purchasing high-quality DEF and testing it with a refractometer. You can find your local DEF supplier and the current price of DEF here.

Roadwarrior Takes the Problems Out of Your Aftertreatment

Keeping your aftertreatment system running smoothly extends its life, but it also benefits your engine and your fuel economy. By avoiding these upstream issues, you should experience fewer and shorter regens, and not need to have your DPF professionally cleaned till 200,000 miles.

However, cleaning can’t take away the wear a DPF has sustained. You will still likely need to replace your DPF before the rest of your truck. At Roadwarrior, our aftermarket DPFs, DOCs and SCR systems offer equal or higher performance standards than your original part and are made to meet your exact model.

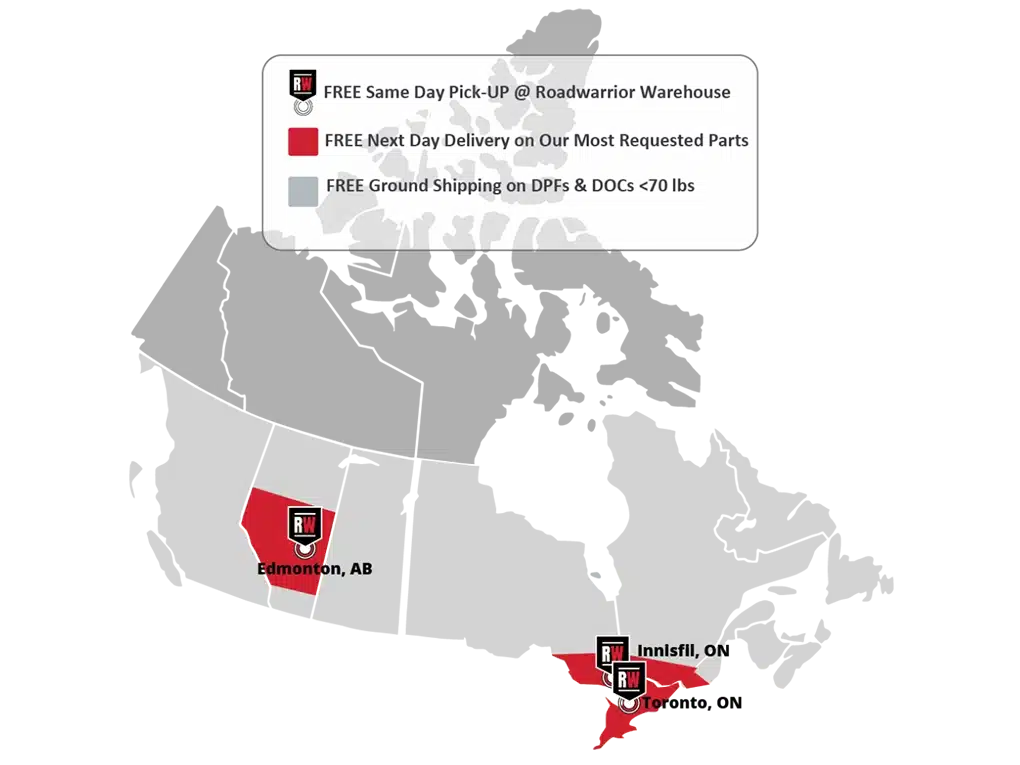

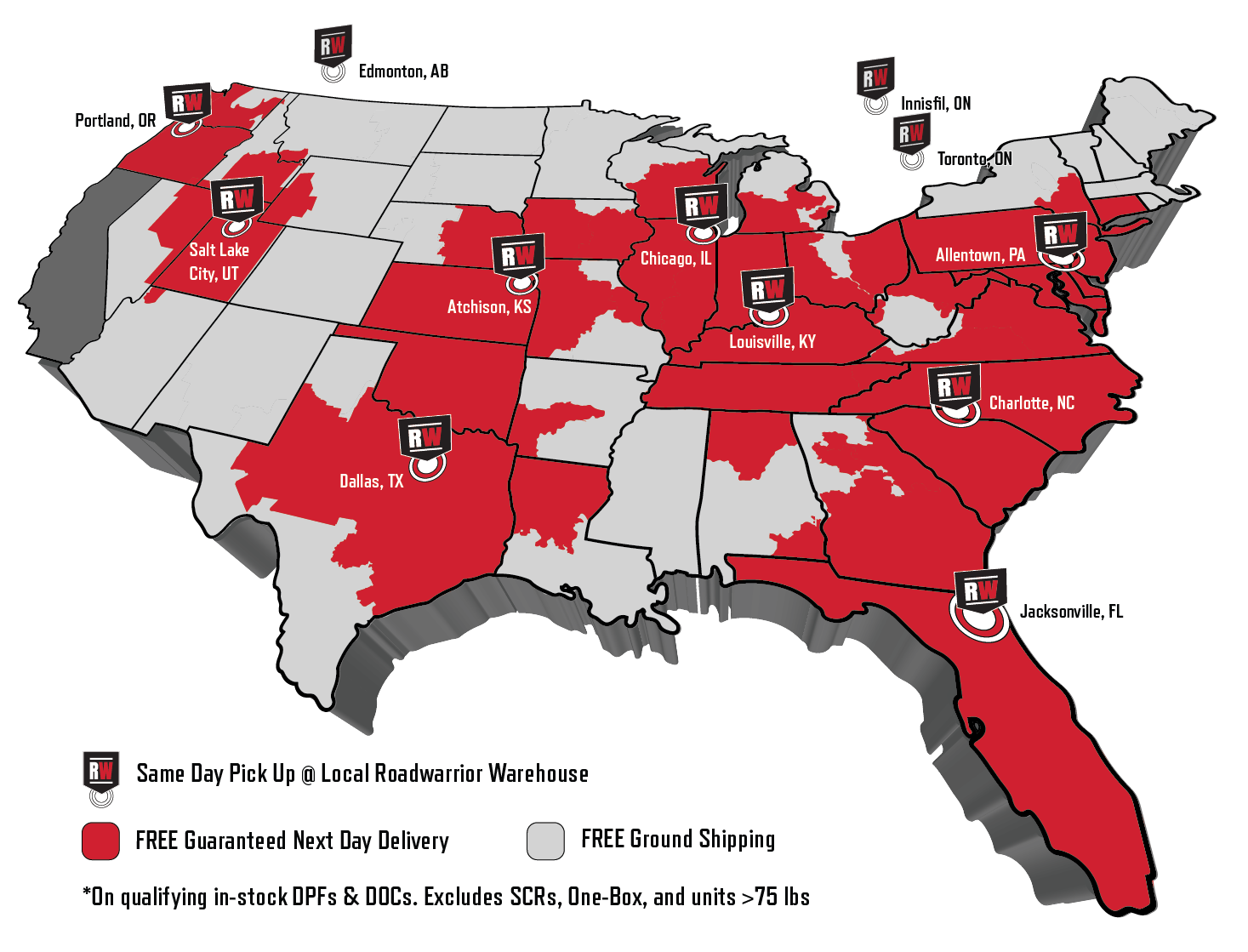

You can order parts through your local distributor, to be shipped in 1-2 days. We also keep our most popular parts constantly in stock and these are available for same-day pickup or next-day delivery.