As a trailblazer in the aftermarket emissions components sector for heavy-duty trucks and buses, Roadwarrior brings a wealth of expertise and a commitment to excellence in every product we offer. Our roots run deep within the industry, backed by the strength and reputation of the DCL Technology Group. This affiliation not only sets us apart as a leader but also enriches our knowledge and capability in the realm of aftertreatment components.

Also under the DCL Technology Group, DCL International, has years of experience designing Evercor® heat exchangers for the power generation, and oil and gas sectors. This expertise in heat exchange technology is directly applicable to the world of EGR coolers, a component critical to the performance and environmental compliance of heavy-duty trucks.

EGR coolers function just like heat exchangers, playing a vital role in enhancing engine efficiency and reducing emissions. Leveraging the combined expertise of Roadwarrior and DCL International, we’re uniquely positioned to offer insights and solutions that are not just industry-leading but also rooted in a deep understanding of thermal management and emission control technologies.

In this article, we aim to share our knowledge about EGR coolers, shedding light on their function, importance, and the best practices for maintaining them. Our goal is to empower heavy-duty truck operators and service professionals with the information and tools they need to ensure optimal performance and compliance with emission standards.

What is an EGR Cooler

The EGR (Exhaust Gas Recirculation) cooler is a pivotal component in modern heavy-duty diesel engines, playing a critical role in reducing emissions and enhancing engine performance. Introduced into the heavy-duty sector as part of the industry’s response to increasingly stringent emission standards, the EGR cooler is designed to lower the temperature of exhaust gases before they are recirculated back into the engine’s intake.

This process is crucial for reducing the formation of nitrogen oxides (NOx), a group of harmful pollutants produced during the combustion process. By cooling the exhaust gases, the EGR cooler helps to limit the temperature in the combustion chamber, thereby reducing the amount of NOx produced. This not only helps vehicles meet emission regulations but also contributes to better air quality.

The EGR cooler’s role in maintaining engine efficiency and compliance with environmental standards makes it an indispensable part of the engine’s aftertreatment system. However, the high temperatures and corrosive nature of exhaust gases mean that EGR coolers must be robust and well-maintained to function effectively. Over time, issues such as internal leaks or clogging can arise, leading to increased emissions, reduced fuel efficiency, and potential damage to the engine and aftertreatment systems.

Given the importance of the EGR cooler in ensuring the smooth operation of heavy-duty trucks, understanding its functionality and the common challenges it faces is crucial. Equally important is adopting best practices and preventive measures to maintain the EGR cooler’s health, ensuring that it continues to contribute to engine performance and emission control.

In the next section, we’ll explore these best practices and preventive measures in detail, providing you with actionable advice to keep your EGR cooler in top condition and your heavy-duty vehicles running efficiently and cleanly.

EGR Cooler Best Practices and Preventive Measures

Maintaining the integrity of EGR coolers is paramount in ensuring the smooth operation of heavy-duty trucks. Regular maintenance and timely interventions can prevent failures and extend the life of these crucial components. Here are some best practices and preventive measures:

- Routine Visual Inspections: Regularly inspect the EGR cooler for any signs of physical damage, corrosion, or leaks. Pay special attention to the hoses and connections, as they are common points for leaks to occur.

- Monitor Coolant Levels and Quality: Keep an eye on the coolant levels and check for any signs of contamination. A drop in coolant levels or the presence of oil in the coolant could indicate a leak in the EGR cooler.

- Check Exhaust Gas Temperatures: Monitor the exhaust gas temperatures. An unexpected increase could be a sign of a clogged or malfunctioning EGR cooler, restricting the flow and causing the exhaust gases to overheat.

- Regular Cleaning: Depending on the manufacturer’s recommendations and the operating conditions, schedule regular cleanings of the EGR cooler to remove soot and other particulates that can lead to clogging and reduced efficiency.

- Be Proactive if Turbo Fails: In the event of a turbo failure, it’s crucial to inspect the EGR system as well. A failed turbo can lead to increased back pressure, potentially causing exhaust gases to bypass the EGR cooler, leading to overheating and damage.

- Regular Inspection of Aftertreatment Components: Regularly inspect the entire aftertreatment system, including the DOC and DPF, for any signs of damage or contamination. Oil or coolant leaking into these components can severely impact their functionality.

- Timely Replacement : Don’t wait for a complete failure. If inspection and diagnostics indicate that the EGR cooler is nearing the end of its service life or is functioning below par, consider a timely replacement with a reliable aftermarket part like those offered by Roadwarrior. This proactive approach can prevent more severe issues down the line and maintain the engine’s efficiency.

By adhering to these best practices and incorporating regular inspections and maintenance into your routine, you can significantly reduce the risk of EGR cooler failures and ensure the optimal performance of your truck’s aftertreatment system.

Ask For New. Ask For Roadwarrior.

In the intricate landscape of heavy-duty trucks and buses, the importance of reliable and efficient aftertreatment components cannot be overstated. Roadwarrior, as a trusted name in the industry, stands at the forefront of providing top-tier, OEM-equivalent EGR coolers and other emissions components. Our commitment to quality, reliability, and innovation is unwavering, ensuring that every part we offer meets the stringent demands of the industry and the expectations of our customers.

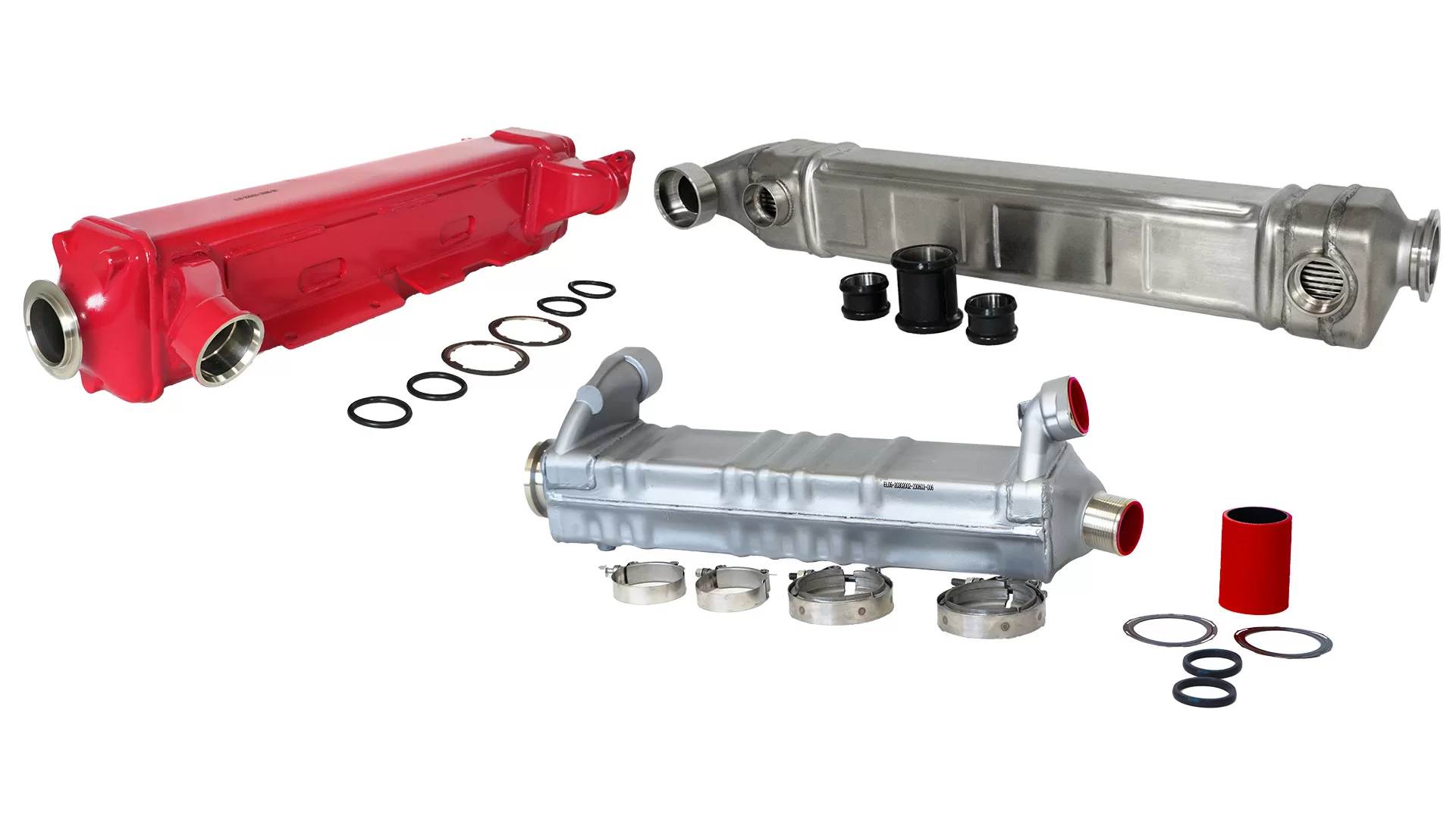

With our roots firmly embedded in the DCL Technology Group, Roadwarrior benefits from a legacy of excellence in thermal management and emissions control solutions. Our range of EGR coolers for Cummins, Volvo, and Detroit Diesel engines exemplifies this commitment, offering a perfect blend of performance, durability, and compliance with emissions standards.

Choosing Roadwarrior means opting for a partner that understands the challenges and demands of the heavy-duty trucking industry. Our products are not just components; they are key to ensuring the smooth operation, efficiency, and environmental compliance of your fleet. Trust Roadwarrior for your EGR cooler needs and experience the peace of mind that comes from partnering with an industry leader dedicated to your success on the road.