The Detroit Diesel DD13 and DD15 engines are renowned for their reliability, power, and efficiency, making them popular choices for heavy-duty trucking. These engines incorporate advanced technology, including the One Box aftertreatment system, which integrates several emissions control components into a single compact unit. This system, while efficient, may require DPF removal and replacement due to clogging from soot accumulation or for cleaning purposes to maintain optimal engine performance and comply with emissions standards.

SPN 3719 or SPN 3251

Fault codes related to DPF issues, such as SPN 3719 for soot accumulation and SPN 3251 for DPF pressure, indicate when maintenance or replacement is necessary. These codes help diagnose issues that can significantly impact engine efficiency and emissions compliance. If you see these, consider cleaning or replacing your DPFs.

Ask for New

While remanufactured DPFs are available, they may not always provide the best solution due to potential variability in quality and longevity. New filters, by contrast, guarantee the highest standards of performance and reliability, ensuring that the engine operates within emissions regulations.

Ask for Roadwarrior

Roadwarrior offers brand new DPFs compatible with specific Detroit Diesel engines. For the DD13 engine, part numbers include A0001403492, A6804910894, A0014903492, and A6804913494. The DD15 engine is compatible with part numbers A6804910494 and A000490369. Additionally, parts A0014907692 and A6804914194 are suitable for both DD13 and DD15 engines, providing a wide range of options for those needing replacements. These parts ensure adherence to OEM standards, offering a reliable solution for maintaining engine performance and emission compliance.

Installing a DPF on a Generation 3, GHG 17 Detroit One Box.

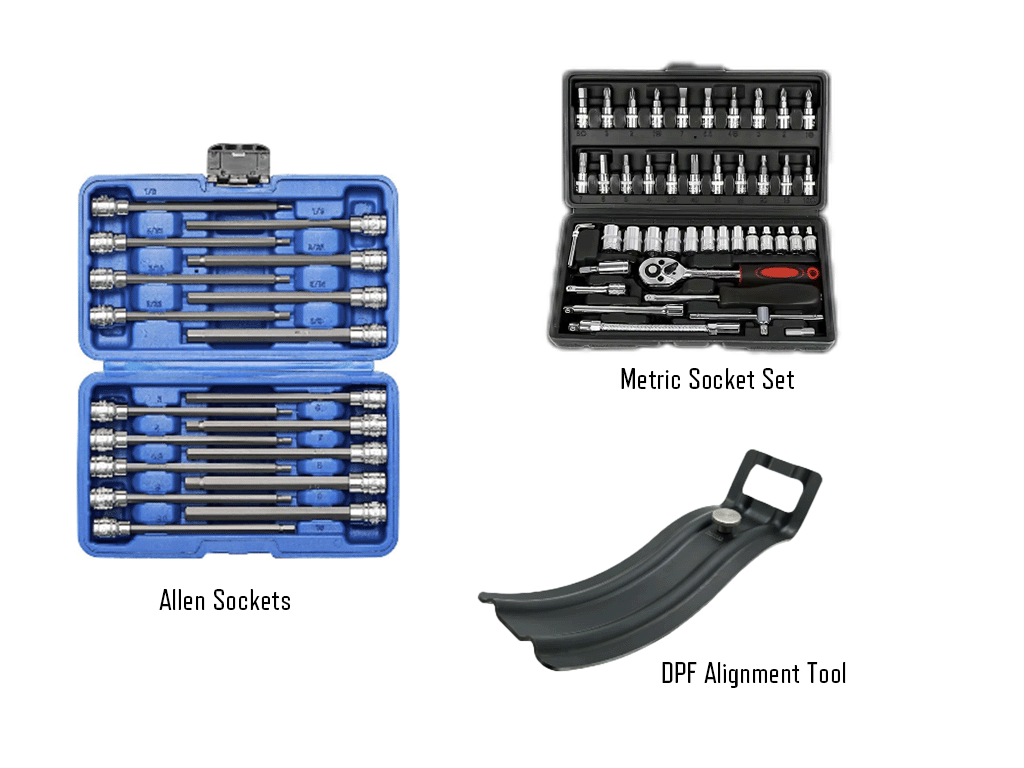

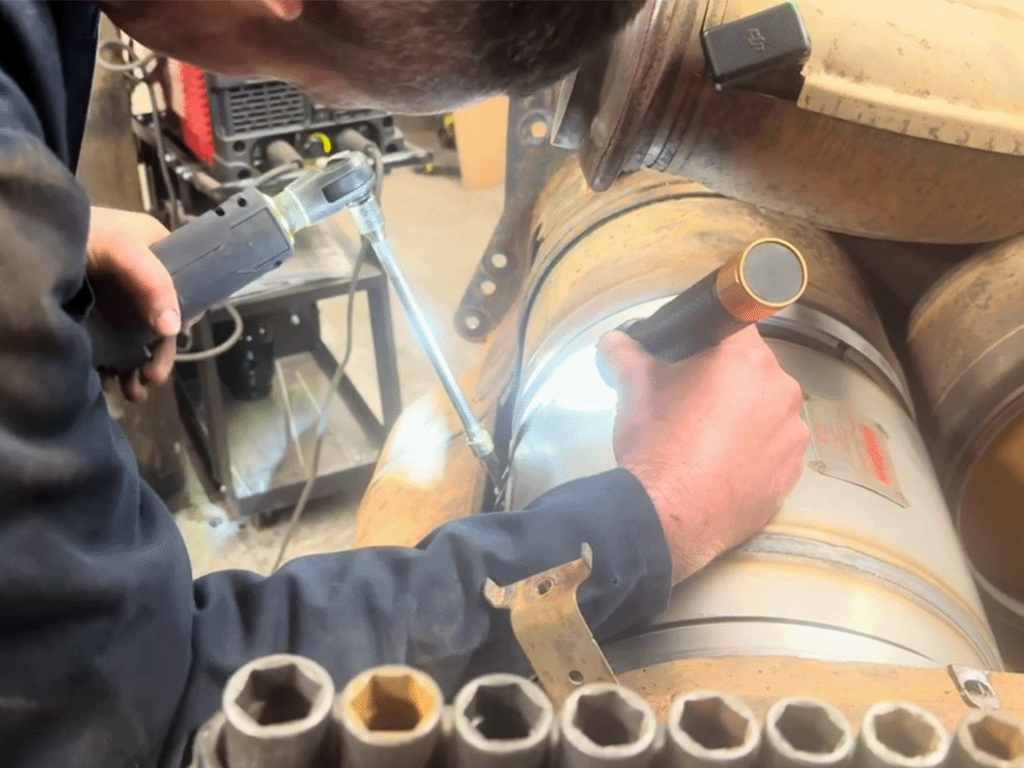

1. Tool Preparation: Gather essential tools, including a Detroit DPF alignment tool, metric socket set, and Allen sockets.

* Optional Tools: While the DPF alignment tool is helpful, it’s not mandatory. Alternative tools may be utilized carefully.

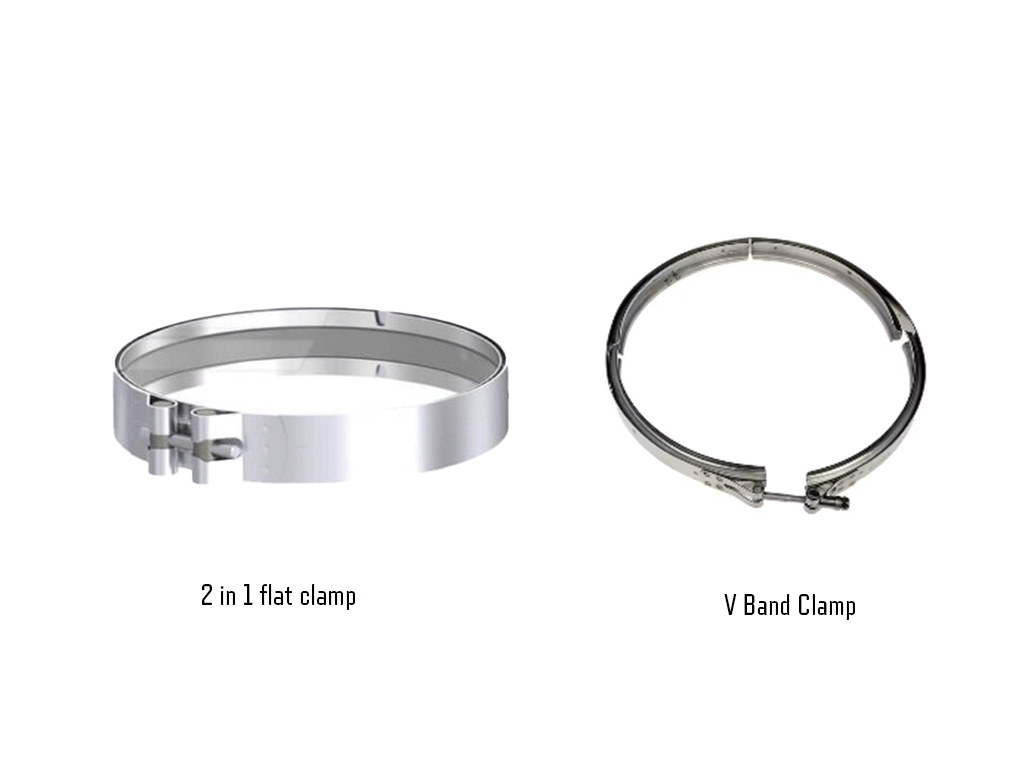

2. Understanding Clamps & gaskets: Familiarize yourself with V-band and 2-in-1 flat clamps with integrated gasket, noting their differences and applications.

3. V Band Clamp on the DOC sideUse a graphite crush gasket for sealing, ensuring its proper placement, with the V-band clamp on the DOC side.

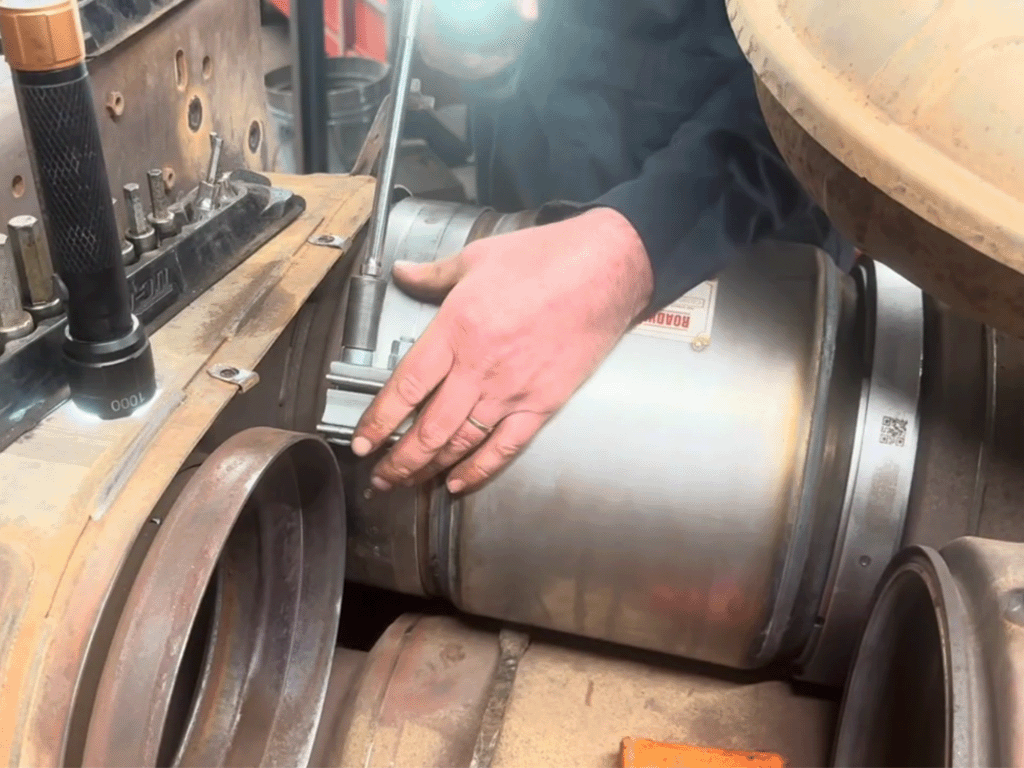

4. 2 in 1 clamp alignment on the inlet side Ensure clamps are correctly aligned and seated, using alternatives to OEM parts for cost efficiency.

When dealing with DPF installation and maintenance on Detroit Diesel engines, it’s essential to use new clamps and gaskets to ensure a proper seal and prevent exhaust leaks. Gaskets should be replaced every time they are removed to maintain integrity. Reusing clamps and gaskets is not recommended, as it increases the risk of leaks. Roadwarrior provides tier 1 clamps and gaskets specifically matched to Detroit Diesel, including V-band clamps (A6809950202, A4709950002), graphite crush gaskets (A6804910480), and 2-in-1 band clamps with graphite gaskets (A6809950302, A0004902241), ensuring precise fit and function.

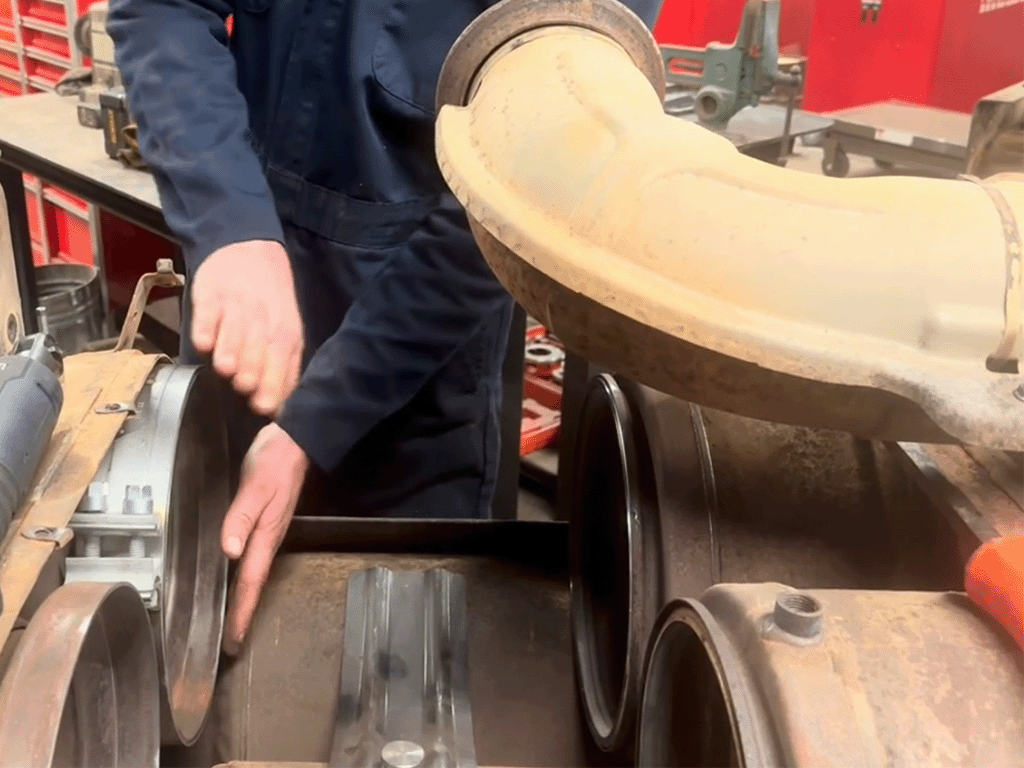

5. Insert and Align the Particulate Filter: Start with the inboard filter for ease of installation, noting its orientation and proper positioning. Precisely align the filter.

6. Ensuring Seal Integrity: Verify the seal’s integrity around the filter, ensuring a leak-proof installation.

7. Adjustment Tips: Make fine adjustments without damaging the filter or gaskets, using strength points for leverage.

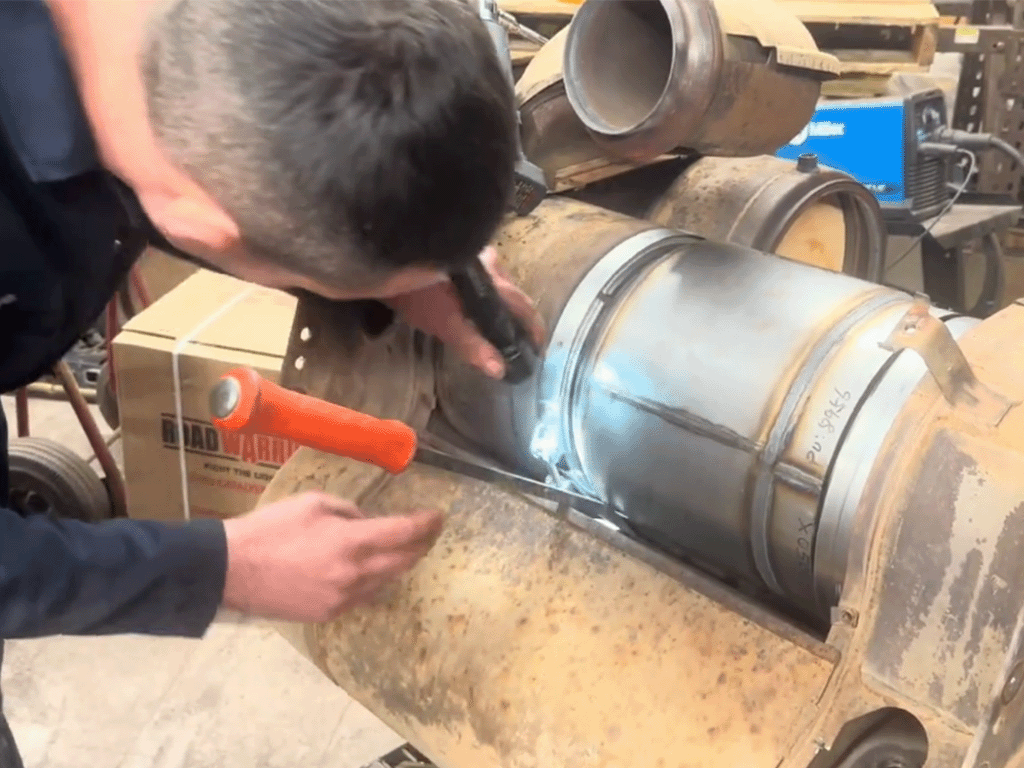

8. Visual Inspection: Use a flashlight to check alignment and seal completeness around flanges.

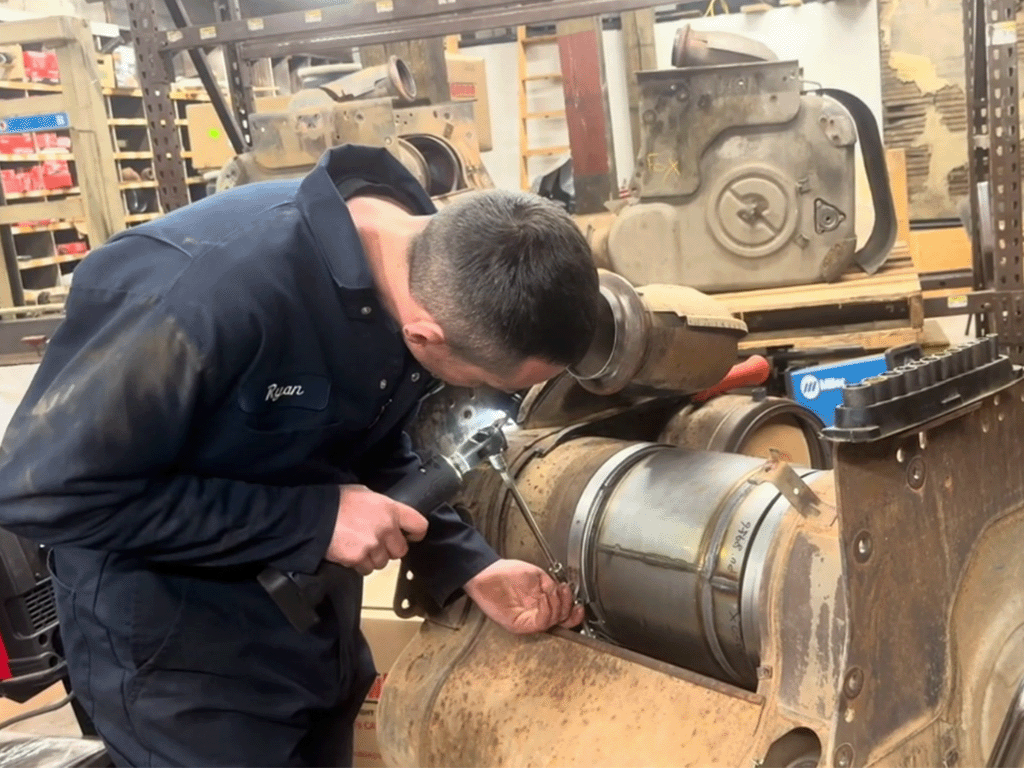

9. Final Adjustments: Make any necessary final adjustments to ensure perfect alignment and sealing. Proceed to tighten clamps, ensuring a secure fit without over-tightening.

10. Quality Check: Conduct a thorough check of all connections, using a flashlight for visual inspection.

11. Installation of second DPF: repeat steps 5-11 to complete installation of second filter, following similar precautions for alignment and sealing.

12. Reassembly and Testing: Once all components are installed, reassemble all removed parts and test the system for functionality.

For those interested in the specifics of DPF installation on Detroit Diesel engines, Ryan Fox of Fox Truck and Tractor has created a comprehensive video demonstration. This video is an excellent resource for understanding the correct procedures, including the use of appropriate clamps and gaskets, to ensure a successful and leak-free installation.