EGR coolers and turbochargers are critical components in the robust engines of heavy-duty trucks, especially those powered by industry giants like Volvo, Cummins, and Detroit Diesel. These parts play a pivotal role not only in ensuring engine efficiency but also in maintaining compliance with stringent emission standards. The EGR (Exhaust Gas Recirculation) cooler helps reduce nitrogen oxide emissions by cooling the exhaust gases before they are recirculated back into the engine. Meanwhile, the turbocharger is essential for boosting engine power by forcing extra compressed air into the combustion chamber, thereby enhancing the engine’s efficiency and power output.

Despite their importance, EGR coolers and turbochargers are not immune to issues. Common problems include leakage in the EGR cooler, which can lead to coolant contaminating the exhaust system, and turbocharger failures, often due to oil contamination or mechanical wear. Such issues don’t just stop at reducing engine performance; they extend their impact to the aftertreatment system. For instance, coolant or oil entering the aftertreatment system through a faulty EGR cooler or turbocharger can lead to significant issues in the Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filter (DPF), hindering their ability to function correctly and potentially leading to costly repairs and downtime. Understanding these challenges is crucial for operators and service professionals who aim to maintain their vehicles’ performance, compliance, and longevity.

The Impact of EGR Coolers & Turbochargers on Engine Efficiency & Performance

EGR coolers and turbochargers are integral to modern heavy-duty truck engines, each serving a critical function in maintaining engine performance and reducing emissions.

EGR coolers play a pivotal role in controlling NOx emissions, a major concern with diesel engines. Essentially functioning as a heat exchanger, the EGR cooler facilitates a crucial interaction between the exhaust gases and the engine’s cooling system. As a portion of the engine’s exhaust gas is redirected back into the intake air, it first passes through the EGR cooler. Here, the exhaust gases come into contact with tubes filled with engine coolant. This process significantly reduces the temperature of the exhaust gases before they re-enter the engine. By cooling these gases, the EGR cooler effectively mitigates the formation of NOx during combustion, contributing to cleaner and more environmentally friendly engine operation. This temperature reduction is vital as it directly influences the engine’s emission profile, ensuring compliance with emission standards and maintaining air quality.

On the other hand, turbochargers are all about enhancing engine efficiency and power. They use the engine’s exhaust gas to drive a turbine, which in turn compresses the intake air. This compression increases the amount of oxygen available for combustion, allowing the engine to burn fuel more effectively and deliver more power without increasing the engine size.

Despite their importance, these components can face various issues. EGR coolers can suffer from leaks, often due to stress from thermal expansion and contraction or from corrosion. When a leak occurs, coolant can enter the exhaust system, leading to white smoke emissions, engine overheating, and contamination of the aftertreatment system. Turbocharger failures, on the other hand, commonly stem from oil contamination, which can clog the turbo’s moving parts, or from mechanical wear and tear. A failed turbocharger can lead to a significant loss in engine power, failure of downstream emissions components, and in some cases, total engine failure if not addressed promptly.

Understanding these components’ roles and the common issues they face is crucial for maintaining the health of the engine and the aftertreatment system, ensuring that heavy-duty trucks continue to perform optimally while meeting emission regulations.

The Domino Effect

When EGR coolers or turbochargers fail, the damage extends beyond the immediate components, setting off a domino effect that can compromise the engine and aftertreatment system.

Failure in EGR coolers often leads to coolant leakage into the engine’s combustion chamber. Incomplete combustion, increased fuel consumption, and elevated smoke emissions result from this leakage. It ultimately leads to a significant drop in engine performance and efficiency. Similarly, a malfunctioning turbocharger, often due to oil leaks or mechanical wear, can reduce the engine’s air intake pressure. This reduction hampers the engine’s ability to efficiently burn fuel, leading to higher fuel consumption and increased emissions.

The implications of these failures don’t stop at the engine. They also pose a significant threat to the aftertreatment system, particularly the Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filter (DPF). Coolant or oil entering the exhaust stream can contaminate these components. In the case of the DOC, such contamination can inhibit its ability to effectively convert harmful gases into less harmful substances. For the DPF, contamination can lead to clogging and increased back pressure. It can also reduce the filter’s ability to regenerate. This not only hampers the filter’s efficiency but can also lead to costly repairs or replacements if not addressed promptly.

Understanding the interconnectedness of these components and the potential cascade of issues stemming from their failure is crucial. Regular maintenance and immediate attention to signs of malfunction are crucial. They ensure the entire system works harmoniously and maintains performance, fuel efficiency, and adherence to emission standards.

Fix it Once

The replacement of the Diesel Oxidation Catalyst (DOC) or Diesel Particulate Filter (DPF) becomes crucial when contaminants like coolant or oil infiltrate the system due to EGR cooler or turbo failures. These contaminants can have detrimental effects on the components, compromising their functionality and leading to a chain of operational issues.

When contaminants such as coolant or oil enter the DOC, they can interfere with the catalyst materials. The DOC is designed to catalyze harmful exhaust gases into less harmful substances through chemical reactions. However, the presence of these contaminants can inhibit these reactions, reducing the efficiency of the DOC. Over time, this can lead to a buildup of unprocessed emissions, increasing the output of harmful pollutants and putting the vehicle at risk of not meeting emission standards.

In the case of the DPF, which is responsible for trapping and storing soot from the exhaust gas, contamination can be particularly problematic. Coolant or oil entering the DPF can lead to clogging, as these substances can solidify or create a coating on the filter material, obstructing the flow of exhaust gases. This obstruction increases the back pressure in the exhaust system, forcing the engine to work harder, which can reduce fuel efficiency and overall engine performance. Moreover, a clogged DPF is unable to regenerate properly – a process where trapped soot is burned off at high temperatures to clean the filter. If regeneration is compromised, the DPF can become overwhelmed with soot, leading to potential system failure and the need for costly repairs or replacements.

Therefore, it’s imperative to address any EGR cooler or turbocharger issues promptly. Consider replacing the DOC or DPF if there’s any sign of contamination. Doing so ensures the longevity and efficiency of the aftertreatment system, maintaining the vehicle’s performance and compliance with emission standards.

Volvo EGR Cooler Problems and Solution

Volvo‘s heavy-duty trucks are known for their reliability and performance, but like all complex machinery, they are not immune to the common issues that can arise with EGR coolers and turbochargers. For Volvo trucks, one of the prevalent issues with EGR coolers is the tendency for internal leaks to develop over time. These leaks can lead to coolant entering the exhaust system, impacting combustion efficiency and potentially damaging components downstream in the aftertreatment system.

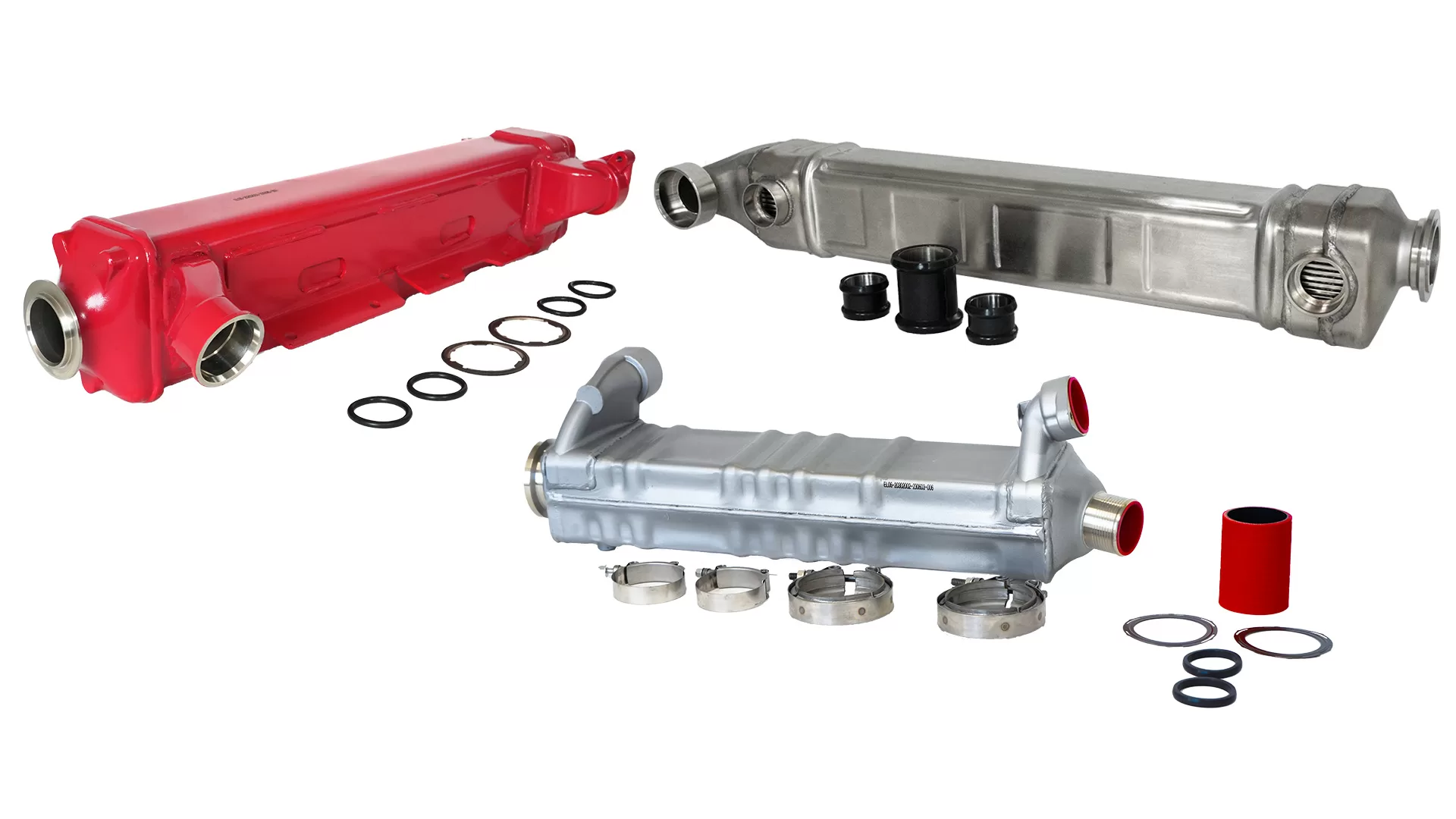

Roadwarrior, with its deep understanding of these common challenges, has been proactive in developing high-quality replacement solutions specifically designed to address and mitigate these issues. For Volvo EGR coolers, Roadwarrior offers robust replacements with part numbers 21480645 and 85136428. Engineering teams precisely engineer these parts to ensure a perfect fit and optimal performance, reflecting the quality and reliability operators expect from Volvo machinery. By choosing Roadwarrior’s replacement solutions, operators can ensure their Volvo trucks maintain their performance, efficiency, and compliance with emission standards, even in the face of the most common EGR and turbo-related challenges.

Cummins EGR Cooler Problems and Solution

Cummins engines are renowned for their durability and power, but even these robust engines can encounter issues with EGR coolers. A common challenge faced by Cummins EGR coolers is the deterioration of internal components due to the extreme temperature variations and corrosive nature of exhaust gases. This deterioration can lead to leaks, allowing coolant to mix with exhaust gases, which can adversely affect engine performance and increase the risk of damage to the aftertreatment system.

Aware of the prevalence and impact of these issues, Roadwarrior has taken proactive steps to provide a high-quality, reliable solution for Cummins engine operators. Roadwarrior’s replacement EGR coolers are not just parts; they are a culmination of meticulous research and an in-depth understanding of the Cummins engines’ operational dynamics. Roadwarrior offers OEM-equivalent replacements for a wide range of Cummins EGR cooler part numbers, ensuring a comprehensive coverage for various models.

Among the most popular Roadwarrior replacements for Cummins EGR coolers are part numbers 33015721, 3688603, 3689051, 3689208, 3689565, and 40195112. Engineers design each part to meet the rigorous durability and performance standards that Cummins engine operators expect. Choosing Roadwarrior’s replacement EGR coolers allows operators to confidently address common issues. This ensures Cummins engines maintain the power and efficiency needed for demanding applications.

Detroit Diesel EGR Cooler Problems and Solution

Detroit Diesel engines, known for their performance and reliability in heavy-duty applications, also encounter their share of challenges with EGR coolers. The most frequent issues with Detroit Diesel EGR coolers revolve around the cooler’s susceptibility to clogging and internal leaks. Over time, soot and other particulates can accumulate within the cooler, leading to reduced efficiency and potential overheating. Similarly, harsh operating conditions cause wear and tear on internal components. This can result in coolant leaks, compromising engine performance and risking aftertreatment system damage.

Roadwarrior, recognizing the critical nature of these common failures, has committed itself to developing high-quality replacement solutions for Detroit Diesel engines. By thoroughly understanding the operational stresses these EGR coolers undergo, Roadwarrior has engineered replacements that address and rectify these common issues, ensuring longevity and reliability.

For operators of Detroit Diesel engines, Roadwarrior offers OEM-equivalent replacements that are not just parts but solutions to enhance engine performance and reliability. The Roadwarrior replacement part numbers for Detroit Diesel EGR coolers include 4731400375, 4731400575, and EA4721400475. Designers meticulously craft each replacement cooler to meet the exacting standards of Detroit Diesel engines, ensuring a perfect fit and optimal function. With Roadwarrior’s replacements, operators can effectively tackle the frequent issues associated with EGR coolers, securing the efficiency and durability of their Detroit Diesel engines for the long haul.

Trust Roadwarrior

For more insights into maintaining the health and efficiency of your EGR coolers, be sure to check out our upcoming articles on the Roadwarrior Blog. We’ll delve into best practices and prevention strategies, helping you keep your heavy-duty trucks running smoothly.

In closing, it’s crucial to recognize the importance of maintaining EGR coolers and turbochargers. They are key components of your vehicle’s aftertreatment system. Their proper function is essential for the engine’s performance. It also ensures compliance with emission standards and operational efficiency. Regular maintenance and timely intervention are your best defense against unexpected downtime and costly repairs.

When it comes to replacements, choosing quality parts is paramount. Roadwarrior’s range includes high-quality, OEM-equivalent EGR coolers known for reliability and performance. These coolers ensure your heavy-duty truck continues to meet the demands of the road. With Roadwarrior, you’re not just investing in a part; you’re investing in peace of mind. You’re also investing in the prolonged health and performance of your vehicle’s crucial systems. Remember, when performance matters, Roadwarrior is the name you can trust.